Our Product

FH-X5-10ZI

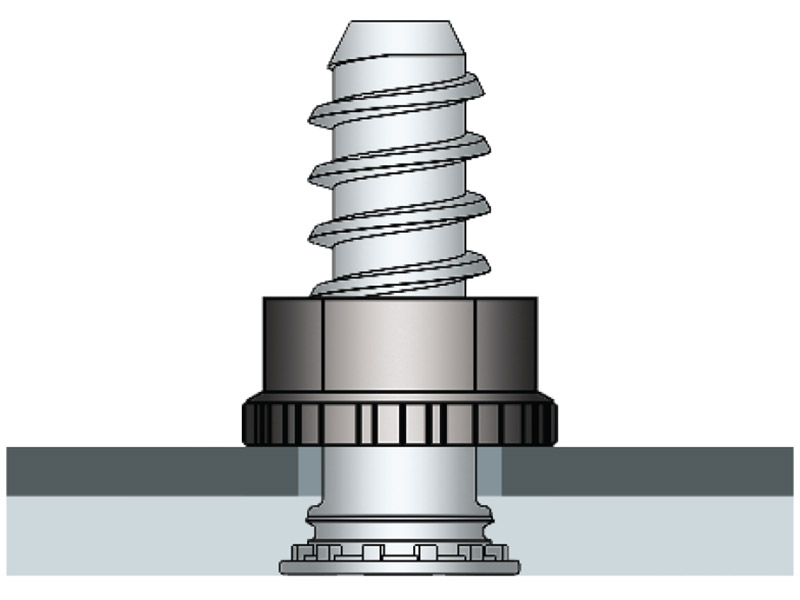

Flush-Head Studs with X-Press™ Thread Profile – Type FHX –

PEM® self-clinching, flush-head studs with X-Press™ threads are typically usedwith push-on or other plastic fasteners. The coarse thread design of the threadreduces assembly time and provides high retention force.These self-clinching studs are installed in metal sheets by pressingthem into place with any standard press. They can also be installed usingautomated equipment during the in-die process.PEM® studs with X-Press™ threads are available with 5 mm and 6 mm metricthreads. Lengths range from 10 mm to 25 mm.

Features and Benefits

Offers fast, reliable attachment.

Reduces assembly time.

Allows for lighter assembly.

Self-clinching stud mounts flush inmetal sheets as thin as 1mm.

Thread design accommodates paintsand coatings without compromisingperformance.

Self-clinching technology is cleanerand has a more attractive finishedappearance than welding.

Can be installed during the stampingprocess with PEMSERTER® in-dietechnology.

Available on Pre-order

L/T "4 - 8 Weeks"

Login/Register to order!

| Thread Code | |

|---|---|

| Thread Size | |

| Thread Size X Pitch | |

| Fastener Material | |

| Standard Finish | colorless, SC1 (5µm), Type III, Zinc plated per ASTM B633, Zinc plus Clear Chromate |

| For Use in Sheet Hardness | |

| Length Code | |

| Product Category | |

| CAD Supplier | |

| CADPartID | |

| Application Type | Automotive Electronics, Datacom, Electric Vehicle Chargers, Industrial, Medical, Telecom |

| Base Panel Material | |

| Brand | |

| Fastener Characteristics | |

| Industry | Automotive Electronics, Datacom & Telecom, Industrial & Commercial, Medical |

| Product Type | |

| Technology Type | |

| Unit (Metric/Unified) | |

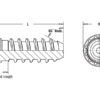

| H ± 0.4_mm | |

| Hole Size in Sheet + 0.08_mm | |

| L Len Pm 015in Or 4mm | |

| Min. Sheet Thickness_mm | |

| S Max._mm |