5 Ultimate Steps to Choosing the Right PEM Fastener for Your Projects

Hoidan, a leading distributor of PEM fasteners, introduces a comprehensive guide detailing a five-step process for selecting the ideal PEM fastener for your design projects. This article delves into crucial considerations such as material compatibility, load requirements, balancing resistance and strength, and the significance of choosing a reputable manufacturer like PEM to guarantee project success and durability. By emphasizing the need to address specific project requirements, including preventing galvanic corrosion and selecting the correct thread size, this guide underscores Hoidan’s dedication to providing top-quality fastening solutions.

Table of Contents

Step One: Material and Application Consideration for Optimal PEM Fastener Selection

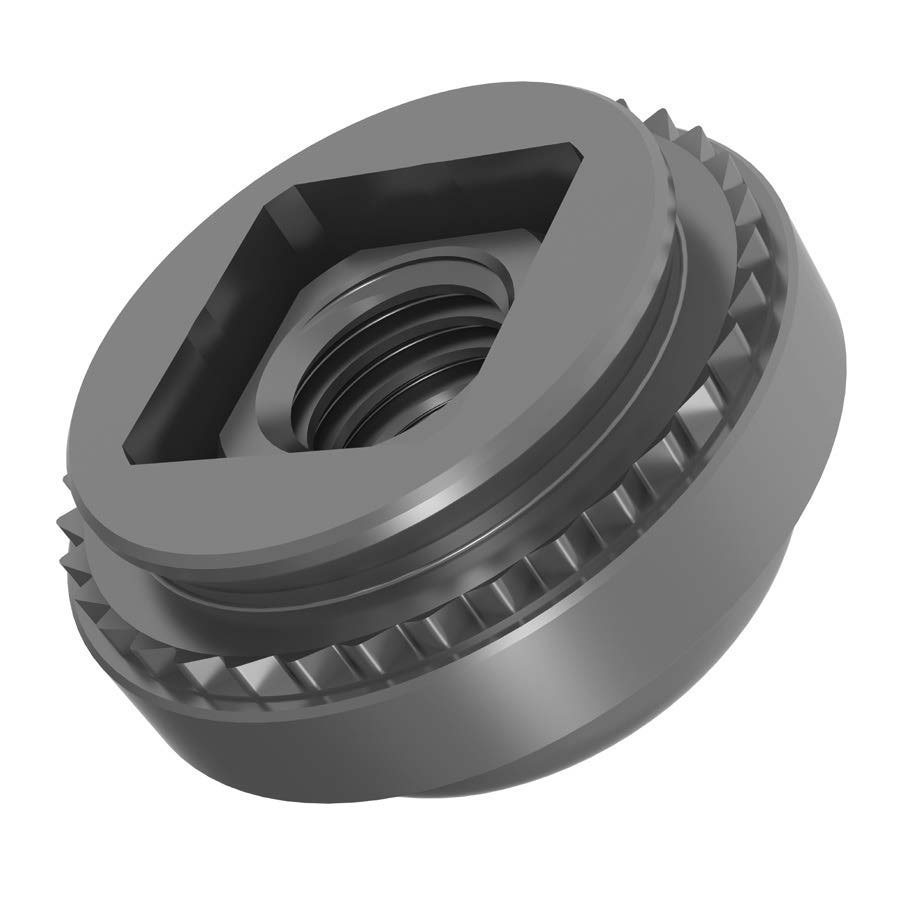

When selecting the right PEM fastener for your project, it’s essential to dive deep into the materials and application specifics. A wide array of fasteners like nuts, bolts, rivets, and washers exists, each suited for particular needs.

Understanding the nuances of material compatibility is key—whether it’s avoiding galvanic corrosion or preventing thread galling. Moreover, the installation process plays a crucial role, demanding precise knowledge of each fastener’s requirements and the best practices for their application.

By consulting with seasoned suppliers, you gain insights into selecting a fastener that not only matches the hardness of your base panel material but also meets the unique demands of your industry.

Whether it’s a self-clinching fastener for an aluminium panel or choosing between steel and stainless options, the right guidance ensures a seamless match for strength, durability, and project success.

Remember, the installation method can significantly affect the outcome, making it imperative to choose techniques that allow for the material’s natural properties to be fully utilised without compromising the fastener’s integrity.

Step Two: Adhering to Load Requirements for PEM Fastener Selection

Understanding the specific load requirements of your project is crucial in selecting PEM fasteners that ensure both the integrity and safety of your design. It involves evaluating the weight and characteristics of the materials involved to determine the appropriate fastener type.

Selecting fasteners with the right thread size and material ductility is essential for meeting these load demands effectively, without sacrificing project efficiency or durability. For applications involving self-clinching fasteners, it’s important to choose fasteners that are compatible with the ductility and thickness of the panel material, ensuring a secure and reliable installation.

This careful consideration guarantees that the chosen PEM fasteners will support the project’s load requirements optimally.

Step Three: Achieving a Balance between Resistance and Strength

Ensuring your PEM fasteners possess the appropriate tensile strength and resistance capabilities is crucial for the durability and reliability of your project. It’s essential to select fasteners that meet the specific requirements of your materials, particularly in preventing thread galling in softer metals under high pressure.

Understanding the unique needs when applying force to components like stainless steel or aluminium is key. Fasteners must be designed to withstand such conditions without compromising integrity, highlighting the importance of choosing fasteners with the right balance of strength and resistance to suit your project’s demands effectively

Step Four: Understanding Installation Needs

Proper installation is pivotal for leveraging the full potential of PEM fasteners in any project. The process varies significantly, with certain applications demanding specialised tools to achieve a secure and damage-free integration of the fastener.

This step underscores the necessity of adhering to precise installation methods to ensure the fastener’s performance is maximised, highlighting the importance of both the selection and the correct use of PEM fasteners for project success.

Step Five: Choosing a Reliable Manufacturer

Selecting the right manufacturer is pivotal in ensuring the quality and reliability of your fasteners choice. A reputable manufacturer like PEM®, known for its longstanding history of innovation and excellence in fastener technology, is essential for the success of your design project.

Opting for a manufacturer with a robust reputation not only guarantees high-quality fasteners but also access to specialised solutions tailored to your project’s unique needs. For comprehensive support in fastener selection, consider engaging in expert-led training sessions and utilising available guides designed to streamline your decision-making process, ensuring optimal project outcomes.

For your project’s success, consider partnering with Hoidan Company Limited, your trusted distributor specialising in high-quality fastening solutions like PEM fasteners, Speed rivets, and more. With our dedication to excellence since 1984 and based in Hong Kong, serving Italy, England, and various European countries, Hoidan boasts expertise across various industries, Hoidan is committed to providing the perfect fastening solution for every application. Let us elevate your project with our proven expertise and tailored solutions.

Reach out to Hoidan today and secure the best in fastening technology.