我們的產品

B-M4-2ZI

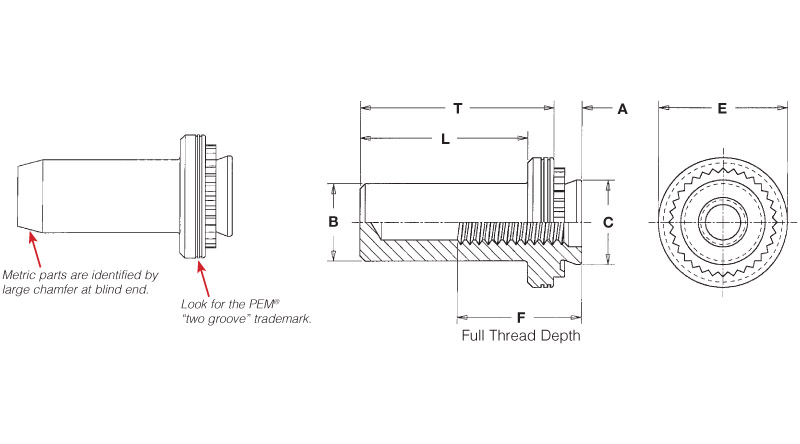

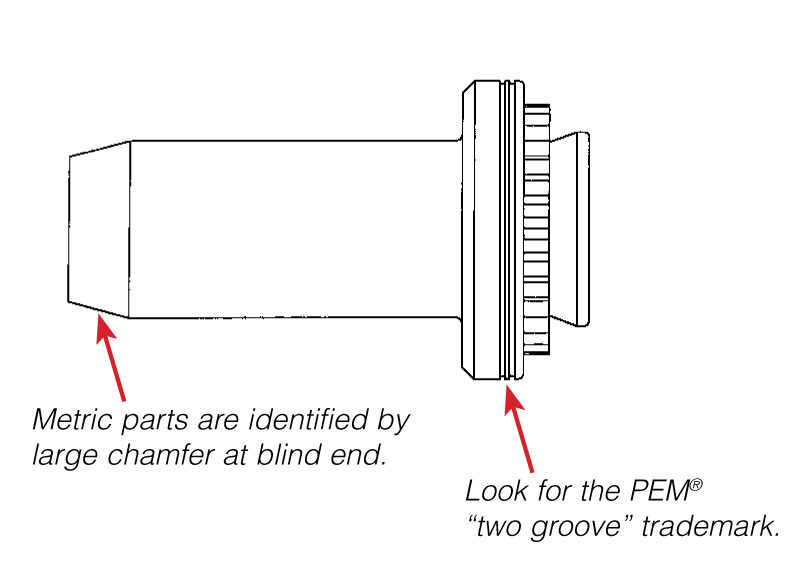

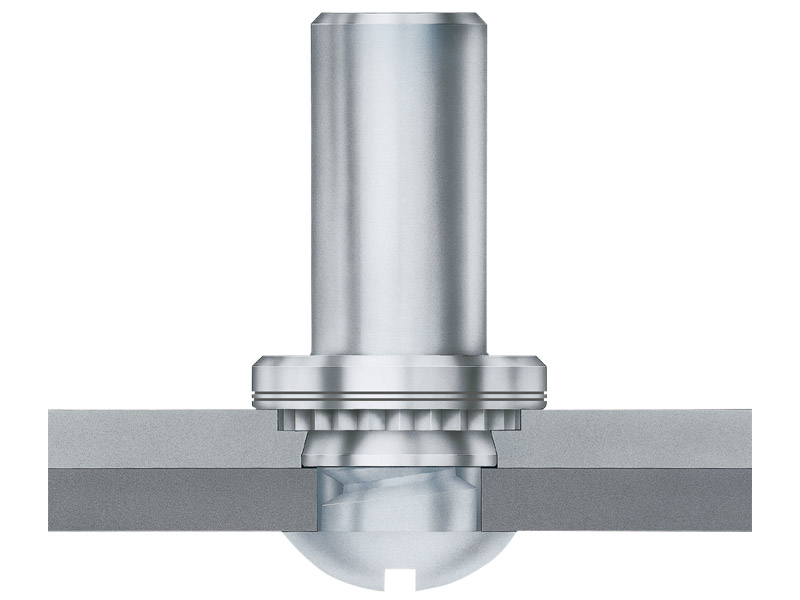

壓鉚盲孔緊固件 – B 型、BS 型

PEM® 品牌自壓鉚盲孔緊固件在薄至1 毫米的金屬板上提供永久安裝的盲孔螺紋。保護螺紋免受異物的影響。設計,可輕鬆安裝在尺寸合適的孔中。 PEM 緊固件的柄部充當自己的飛行員。 PEM 盲孔緊固件可透過任何在平行表面之間施加擠壓力的標準壓力機安裝。為碳鋼或不鏽鋼。

1000 件庫存 (允許無庫存下單)

登入/註冊即可訂購!

| 重量 | 1.39318 公斤 |

|---|---|

| 螺紋代碼 | |

| 螺紋尺寸 | |

| 螺紋尺寸 X 螺距 | |

| 螺紋規格 | |

| 柄部代碼 | |

| 緊固件材質 | |

| 標準表面處理 | colorless, SC1 (5µm), Type III, Zinc plated per ASTM B633, Zinc plus Clear Chromate |

| 用於板材硬度 | |

| 產品分類 | |

| CAD供應商 | |

| 卡帕迪 | |

| 應用程式類型 | Aerospace, Automotive, Automotive Electronics, Commercial Vehicles, Datacom, Electric Vehicle Chargers, Electric Vehicles, Electronics, Industrial, Manufacturing & Sheet Metal Fabrication, Marine, Medical, Renewable Energy, Telecom |

| 基板材料 | |

| 品牌 | |

| 緊固件特性 | |

| 產業 | Automotive, Automotive Electronics, Datacom & Telecom, Electic Vehicles, Industrial & Commercial, Medical |

| PEM 產品系列 | |

| 產品類型 | |

| 技術類型 | |

| 單位(公制/統一) | |

| A 柄最大 | |

| B Max._mm | |

| E ± 0.25_mm | |

| F Min._mm | |

| Hole Size in Sheet + 0.08_mm | |

| L Max._mm | |

| Min. Sheet Thickness_mm | |

| C Max._mm | |

| T ± 0.25_mm |

| THREAD CODE | 440 |

| THREAD SIZE | .112-40 (#4-40), #4-40 |

| THREAD SPECIFICATION | 2B, ANSI B1.1, Internal |

| FASTENER MATERIAL | 300 Series Stainless Steel |

| STANDARD FINISH | Passivated and/or tested, Passivated and/or tested per ASTM A380 |

| FOR USE IN SHEET HARDNESS | HRB 70 / HB 125 or Less |

| PRODUCT CATEGORY | Miniature Self-Clinching Fasteners – Types U, UL, FE, FEO, FEOX, FEX |

| CAD SUPPLIER | PennEngineering® (PEM®) |

| CADPARTID | 103692 |

| THREAD TYPE | Non-Locking |

| APPLICATION TYPE | Automotive Electronics, Consumer Electronics, Datacom, Telecom |

| BASE PANEL MATERIAL | Aluminum, Steel |

| BRAND | PEM |

| FASTENER CHARACTERISTICS | Locking, Miniature, Threaded Internal |

| INDUSTRY | Automotive Electronics, Consumer Electronics, Datacom & Telecom |

| INSTALLATION EQUIPMENT/METHOD | C-Frame Automatic Feed.ch, C-Frame Manual Feed |

| PRODUCT TYPE | Nuts |

| TECHNOLOGY TYPE | Self-Clinching |

| UNIT (METRIC/UNIFIED) | Unified |

| A SHANK MAX | .060in, 0.06in |

| C + .000 – .005_IN | .171in |

| E ± .005_IN | .192in |

| HOLE SIZE IN SHEET + .003 – .000_IN | .172in |

| MAX. HOLE IN ATTACHED PARTS_IN | .132in |

| MIN. DIST. HOLE C/L TO EDGE_IN | .14in |

| D MAX._IN | .145in |

| SHEET THICKNESS_IN | .059 to .070in |

| T + .015 -.000_IN | .065in |

Resources

Catalog

Installation & Performance Data

| TYPE | THREAD SIZE | SHANK CODE | TEST SHEET THICKNESS | TEST SHEET MATERIAL | INSTALLATION (kN) | PUSHOUT (N) | TORQUE-OUT (N•m) |

|---|---|---|---|---|---|---|---|

| B, BS | M3 | 1 | 1.0 | 5052-H34 Aluminum | 7.1 | 400 | 1.15 |

| B, BS | M3 | 2 | 1.4 | 5052-H34 Aluminum | 9 | 750 | 1.47 |

| B, BS | M4 | 1 | 1.0 | 5052-H34 Aluminum | 8.9 | 470 | 2.6 |

| B, BS | M4 | 2 | 1.4 | 5052-H34 Aluminum | 12.5 | 970 | 4 |

| B, BS | M5 | 1 | 1.0 | 5052-H34 Aluminum | 9.3 | 480 | 3.6 |

| B, BS | M5 | 2 | 1.4 | 5052-H34 Aluminum | 14 | 845 | 5.7 |

| B, BS | M6 | 1 | 1.4 | 5052-H34 Aluminum | 17.8 | 1400 | 10.2 |

| B, BS | M6 | 2 | 2.3 | 5052-H34 Aluminum | 17.8 | 1400 | 10.2 |

| B, BS | M3 | 1 | 1.0 | Cold-Rolled Steel | 11.1 | 550 | 1.5 |

| B, BS | M3 | 2 | 1.4 | Cold-Rolled Steel | 14 | 1010 | 2.05 |

| B, BS | M4 | 1 | 1.0 | Cold-Rolled Steel | 15.6 | 600 | 3.4 |

| B, BS | M4 | 2 | 1.4 | Cold-Rolled Steel | 20 | 1250 | 5.1 |

| B, BS | M5 | 1 | 1.0 | Cold-Rolled Steel | 17.8 | 620 | 4 |

| B, BS | M5 | 2 | 1.4 | Cold-Rolled Steel | 25 | 1112 | 6.8 |

| B, BS | M6 | 1 | 1.4 | Cold-Rolled Steel | 25.7 | 1760 | 11.9 |

| B, BS | M6 | 2 | 2.3 | Cold-Rolled Steel | 25.7 | 1760 | 11.9 |

| TYPE | THREAD CODE | SHANK CODE | TEST SHEET THICKNESS | TEST SHEET MATERIAL | INSTALLATION (lbs.) | PUSHOUT (lbs.) | TORQUE-OUT (in. lbs.) |

|---|---|---|---|---|---|---|---|

| B, BS | 440 | 1 | 0.040 | 5052-H34 Aluminum | 1600 | 90 | 10 |

| B, BS | 440 | 2 | 0.056 | 5052-H34 Aluminum | 2000 | 170 | 13 |

| B, BS | 632 | 1 | 0.040 | 5052-H34 Aluminum | 1800 | 95 | 17 |

| B, BS | 632 | 2 | 0.056 | 5052-H34 Aluminum | 2800 | 190 | 22 |

| B, BS | 832 | 1 | 0.040 | 5052-H34 Aluminum | 2000 | 105 | 23 |

| B, BS | 832 | 2 | 0.056 | 5052-H34 Aluminum | 3000 | 220 | 35 |

| B, BS | 024 | 1 | |||||

| B, BS | 024 | 2 | |||||

| B, BS | 032 | 1 | 0.040 | 5052-H34 Aluminum | 2100 | 110 | 32 |

| B, BS | 032 | 2 | 0.056 | 5052-H34 Aluminum | 3500 | 190 | 50 |

| B, BS | 0420 | 1 | 0.056 | 5052-H34 Aluminum | 4000 | 315 | 90 |

| B, BS | 0420 | 2 | 0.090 | 5052-H34 Aluminum | 4000 | 315 | 90 |

| B, BS | 440 | 1 | 0.040 | Cold-Rolled Steel | 2500 | 125 | 13 |

| B, BS | 440 | 2 | 0.056 | Cold-Rolled Steel | 3500 | 230 | 18 |

| B, BS | 632 | 1 | 0.040 | Cold-Rolled Steel | 3000 | 130 | 18 |

| B, BS | 632 | 2 | 0.056 | Cold-Rolled Steel | 4000 | 260 | 28 |

| B, BS | 832 | 1 | 0.040 | Cold-Rolled Steel | 3500 | 135 | 30 |

| B, BS | 832 | 2 | 0.056 | Cold-Rolled Steel | 5000 | 285 | 45 |

| B, BS | 024 | 1 | |||||

| B, BS | 024 | 2 | |||||

| B, BS | 032 | 1 | 0.040 | Cold-Rolled Steel | 4000 | 140 | 35 |

| B, BS | 032 | 2 | 0.056 | Cold-Rolled Steel | 5000 | 250 | 60 |

| B, BS | 0420 | 1 | 0.056 | Cold-Rolled Steel | 6000 | 400 | 105 |

| B, BS | 0420 | 2 | 0.090 | Cold-Rolled Steel | 6000 | 400 | 105 |